Pharmaceutical HVAC Systems

Pharmaceutical HVAC Systems

MegaTec Company can

complete all

project HVAC phases

from initial programming, conceptual design

through execution, validation and facility commissioning.

We create concepts and deliver solutions that enhance a client’s competitive advantage.

In design and execution aspect, MegaTec has multi-discipline engineers with background in mechanical, filtration, plumbing, fire protection, electrical/lighting,

instrumentation, controls, telecommunications and industrial process cooling systems.

Our team have successfully designed and executed many large projects.

We create concepts and deliver solutions that enhance a client’s competitive advantage.

In design and execution aspect, MegaTec has multi-discipline engineers with background in mechanical, filtration, plumbing, fire protection, electrical/lighting,

instrumentation, controls, telecommunications and industrial process cooling systems.

Our team have successfully designed and executed many large projects.

Our cleanroom expertise can be found in the following industries

Pharmaceutical – CGMP

drug manufacturing,

Healthcare – Operating room, isolation room and protective environment.

Semiconductor/Electronics – Computer chips & wafer, circuit boards & switch manufacturing.

Automotive – Fuel injector assembles, paint shop, electronics assemblies.

Research – R&D, DNA, Nano and

bio-hazard/clean labs.

Others – Film manufacturing, eye-care products & plastics molding

bulk chemical synthesis, tablet, injectable and oral packaging, barrier isolation/containment, automated processing and bio-pharmaceutical R&D facilities.

Healthcare – Operating room, isolation room and protective environment.

Semiconductor/Electronics – Computer chips & wafer, circuit boards & switch manufacturing.

Automotive – Fuel injector assembles, paint shop, electronics assemblies.

Research – R&D, DNA, Nano and

bio-hazard/clean labs.

Others – Film manufacturing, eye-care products & plastics molding

We also conduct studies and perform services in the following areas

Regulatory compliances.

Feasibility study.

Process emission study.

Processing environment indoor air quality study.

Central utility, chemical distribution and DI systems

ISO based performance and qualification(s) testing with precision, research-grade equipment and instruments which are calibrated and conform CFR 21 requirements

Commissioning and validation

CFD simulation to optimize cleanroom airflow patterns

Field-based air quantity modeling to prevent airflow over-supply and reduce fan energy waste

Strategies to reduce particle or

bio-microorganism across contamination and energy auditing

Cleanroom research projects funded by governmental, research institutions and private industries

Feasibility study.

Process emission study.

Processing environment indoor air quality study.

Central utility, chemical distribution and DI systems

ISO based performance and qualification(s) testing with precision, research-grade equipment and instruments which are calibrated and conform CFR 21 requirements

Commissioning and validation

CFD simulation to optimize cleanroom airflow patterns

Field-based air quantity modeling to prevent airflow over-supply and reduce fan energy waste

Strategies to reduce particle or

bio-microorganism across contamination and energy auditing

Cleanroom research projects funded by governmental, research institutions and private industries

Our Goal

With client’s mission in mind, we deliver innovative, cost-effective solutions that translate into a measurable competitive edge for our customers. Our project success can be measured by technical superiority, adaptability, constructability, reliability, maintainability, safety and energy efficiency.

MegaTec can help you to certify your Cleanroom

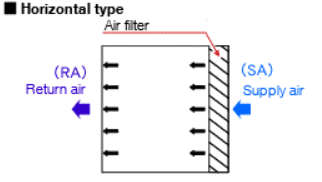

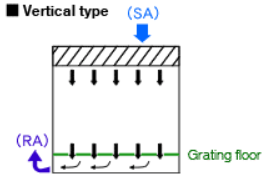

Unidirectional Flow Cleanroom Type

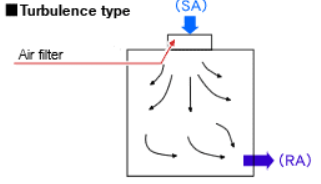

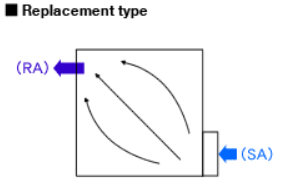

Nonunidirectional Flow Cleanroom Type

Nonunidirectional Flow Cleanroom Type

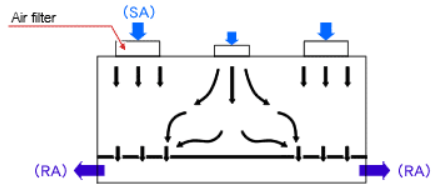

Combined (mixed) Flow Cleanroom Type

Vertical type